WhatsApp)

WhatsApp)

Cement Manufacturing Process Phases. Production of cement completes after passing of raw materials from the following six phases. These are; Raw material extraction ...

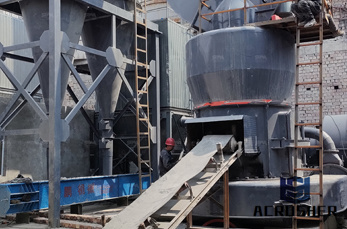

3 These differences between cement grinding and grinding of raw materials made it a serious challenge to obtain a good performance of a vertical roller mill in cement

Cement Mill Noise Level and Attenuation Report Page 3 2. Introduction This study was conducted to evaluate noise levels of both conventional ball mills and vertical ...

Chapter 93. Construction HEALTH AND SAFETY HAZARDS IN THE CONSTRUCTION INDUSTRY. James L. Weeks. Construction workers build, repair, maintain, renovate, .

Loesche has provided a LM 56 3+3 CS vertical roller mill to Attock Cement Pakistan Ltd, for the grinding of cement clinker. The new mill will be used in the new line ...

calculators, engineering, mechanical, electrical, electronics, design, construction, manufacturing, consultant, layout, software, chemical, plastic, polymers

Cedar LAP Siding * Shiplap, Dutch Lap, Channel Rustic Patterns * Cedar Siding LAP Siding Prices, Patterns, and Pictures

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for ...

Click here for Page two the 1999 update. Eddie''s Portable Chain Saw Mill the Ladder Mill. 1998 vintage. A home made elcheapo mill. Click here some scans of ...

Cement history, in brief, from the Greeks and Romans to the development of Portland cement

Manufacturing the cement kiln. Most Portland cement is made in a rotary kiln. Basically, this is a long cylinder rotating about its axis once every minute or two.

Cement is a global commodity, manufactured at thousands of plants. The industry is consolidating globally, but large international firms account for only 30% of the ...

The emergence of China as a global economic force has influenced the technical enterprise generally and a number of industries specifically.

Evaluating cement bond. Acoustic logs do not measure cement quality directly, rather, this value is inferred from the degree of acoustic coupling of the cement to the ...

The Home Owner Brant of Connecticut. The Wood Species Redwood Siding. The Wood Grade Redwood Clear All Heart (CAH) .

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

Resources include AIA contract documents, handbooks, guidelines, and MasterSpec.

A cement process engineer handles the various production stages of cement production in a factory as portrayed in this sample resume.

Grinding media. Grinding balls are only one type of grinding media. Grinding media are the means used to crush or grind material (cement, mineral, .) in a mill.

Chemical Considerations. The raw material preparation stage of cement manufacture results in the production of a rawmix that is in a suitable state for feeding to the ...

Homogenising store The stacker is mounted on the centre column, which allows rotation in both directions simultaneously with the vertical movement of the jib.

Epoxy Granite Filling an Industrial Hobbies RF45 Mill for Vibration Dampening and Rigidity. Filling the machine castings with Epoxy Granite (sometimes ...

James Hardie is the world leader in fiber cement siding and backerboard. We''ve been providing a better way to build for over 100 years.

Sep 17, 2013· This video provides an overview of how to perform Critical Path Method (CPM) to find the Critical Path and Float using a ...

WhatsApp)

WhatsApp)