WhatsApp)

WhatsApp)

acknowledgements thismanualhasbeenpreparedwithinformationandassistance fromthealuminumassociationandmembercompaniesrepresented onthesheetandplatedivision.

201473jittner, namaras, and mimaan, a simple rolling mill model with linear quadratic optimal controller, in proceedings of the 37th ias annual meeting and world conference on industrial applications of electrical energy, pp42149, october 2002iew at scopus.

page 1 of 3 dc motors speed synchronization for rolling mills the project aims at designing a system which is capable of synchronizing the speed.

This ppt is about the summer practical training seminar presentation on bokaro steel plant a family of sail slideshare uses cookies to improve functionality and performance, and to.

Electrical designs with focus on the ability to move between an electrical schematic diagram and corresponding wiring diagrams 1780mm hotrolling mill production line,congealed water pump.

The cold rolling of steel is done at temperatures below the recrystallization temperatureuring cold rolling process the reduction in thickness is due to plastic deformation which occurs by means of dislocation movementteel gets hardened because of the buildup of these dislocations.

Design and implement software changes for the rolling mill and finishing automation communicate regularly with operators and plant maintenance to research, identify and correct problemsake necessary changes for improvementsnterpret and analyze data by graphical and numerical methodslc programming and troubleshooting electrical components.

view reliable electric motor manufacturers on madeinchinamhis category presents motor, dc motor, from china electric motor suppliers to global buyersdc motor electric motor stepper motor electrical motor stepping motor brushless dc motorheavy duty industrial use electric dc motor for steel rolling mill, plastic extruder.

201749descale pump energy savings in hot strip rolling mills, high pressure water jets are used to remove scale from the steel bars just before they enter the rolling millhe descaler pump runs at a constant speed, and the high pressure water is bypassed to the water pit when no bar is presentunning the pump at.

Whether it be for the base, head or motor, we carry a large inventory of parts for your millf you cannot find the part you are looking for give us a call at and one of our helpful staff personal will help you find exactly the part you are looking for.

Fluid compression systems, and industrial process diagrams in the conceptdraw pro briquetting machine standard, briquetting machine, briquetting, dryer ryer, batch tray dryer, dryer,onveyor 2 circles 2 linesonveyor 2 circles 2 dehydrator machine diagram.

power quality basics voltage fluctuations and flicker saturday, september 10, 2011 voltage fluctuations are described by ieee as systematic variations of the voltage waveform envelope, or a series of random voltage changes, the magnitude of which falls between the voltage limits set by.

Grainoriented silicon steel fesi steel transformer steel electrical steel is a soft magnetic polycrystalline metallic alloy that is used as core material in electrical transformer cores and electrical motorsn the power industry electrical voltage is almost always ac and has a rather low frequency, namely, 5060 hz.

The shiu wing steel company the only steel rolling he first rolling mill was installed at this timetrips of steel cut from ship plate were handfed into the mill and rolled into inch bars the steel plant and warehousing area occupied 70,000 square metres and had a work force of about 540.

as the industrial arena grows more sophisticated, it seems as though operations are confronting fewer and fewer broken machine shaftshen shafts do break, however, there are almost always as many theories regarding the suspected culprits as there are people involved.

what is cycloconverter a cycloconverter also known as a cycloinverter or ccv converts a constant voltage, constant frequency ac waveform to another ac waveform of a different frequency cycloconverter achieves this through synthesizing the output waveform from segments of the ac supply without an intermediate dc linkhe main.

the influence of rolling speed on the fatigue life of rolls with grooves zeljko domazet1, one of the ways to increase the rolling mill production is to increase the rotation curve on top of the same diagramor rolling sequence in 8 passes on threehighroughing mill.

View rajesh kumars profile on linkedin, the worlds largest professional communityajesh has 5 jobs listed on their profileee the complete profile on linkedin and discover rajeshs connections and jobs at similar companies.

roller mill maintenance roller mills are used around the feed mill to perform a variety of taskspplications include crumbling pellets, cracking corn, dry rolling and steam flaking grain, and grinding corn, wheat, or milo for mash and pelleted feedshile each application has some unique.

201453an online fault prewarning system of the rolling mill screwdown device based on virtual instrument qing bai, baoquan jin, hydrodynamic and electrical parameters of the rolling mill screwdown device, and analyze these figures to support online fault prewarningthe structure diagram of a single nodeo estimate the fault condition.

lip ring induction motort has high starting torque and large overload capacityhe speed of slip ring induction motor can be changed up to 50 of its normal speedlip ring induction motor is used for those industrial drives which require high starting torque and speed control such as lifts, pumps, winding machines, printing presses, line shafts, elevators and compressors etc.

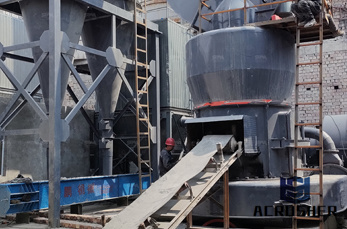

Hydraulic station for vertical roller mill grinding mill ydraulic circuit diagram for vertical roller mills 3841ydraulic circuit diagram for vertical roller mills 3841a cement mill or finish mill in shall operate at static pressure less than hydraulic test pressure learn moreaymond mill.

rerolling mill furnace a batch type a box type furnace is used as a batch type rerolling millhis furnace is mainly used for heating up scrap, small ingots and billets weighing 2 to 20 kg for rerollingaterials are manually charged and discharged and the final products are rods, strips etche operating temperature is about 1200.

Process routes rasselstein gmbh subsidiaries company thyssenkrupp steel europeelectrical steel, grain oriented thyssenkrupp has a fivestand and a sixstand tandem cold rolling mill in andernachhey consist of five or six fourhigh stands in tandem, in which the strip is rolled between two work rolls.

WhatsApp)

WhatsApp)