WhatsApp)

WhatsApp)

Calculate and Select Ball Mill Ball Size for Optimum Grinding. Aug 2, 2013 . In Grinding, selecting (calculate) the correct or optimum ball size that allows for the ...

Cement grinding Vertical roller mills versus ball ... The grinding process in ball mills and vertical roller ... inclination of the particle size distribution curve ...

mineral processing ball mill construction design. Grinding Mill Types, Construction, and Usage . Grinding Mills .Grinding is the second step of mineral processing and ...

Ball Mill Balls on Manufacturer of balls includes ball mill balls. Specifications of ball mills include 12 in. x 12 in. cast iron drum size, 285 ball ...

Planetary Ball MillS 4 applications RETSCH Planetary Ball Mills pulverize and mix soft, mediumhard to extremely hard, brittle and fibrous materials.

EMAX High Energy Ball Mill Retsch. The Emax is an entirely new type of ball mill for high energy milling. ... The novel size reduction mechanism of the E max ...

A ball mill for powerful size reduction and homogenization. RETSCH ball mills are available as mixer mills as well as planetary ball mills.

The ball size in a mill has a significant influence on the mill throughput, ... for industrial mills); ... The optimal ball diameter in a mill 333

how to calculate the ball mill discharge size distribution. Determination of breakage parameters in laboratory scale ball mill ... ball milling is to predict product ...

Ball Mills What Are These ... down to the particle size of 20 to ... This formula calculates the critical speed of any ball mill. Most ball mills operate most ...

Optimum choice of the makeup ball sizes for maximum throughput . Jun 27, 2013 The ball size is one of the critical factors for determining the mill size on the mill ...

ball mill size and motor power requirements. ... The following shows how the size of mill required to draw ... inside the liners whereas Rexnord mills are specified ...

In this guest post, Marcelo Tavares, the head of the Laboratório de Tecnologia Mineral in Brazil talks about the application of DEM to the field of comminution, with ...

Gear Pinnion Drive used on Larger Mills JH 32014 Talk ... Ball Mill Capacity Dimensions Author: jhoffmann Created Date: 3/28/2014 4:20:57 PM ...

BallRod Mills, based on 4″ liners and capacity varying as power of mill diameter, on the 5′ size give 20 per cent increased capacity; on the 4′ size, 25 ...

sizing balls for ball mills . BY admin | April 7th, 2013 . 0. FRITSCH Milling and ... Main features of pebble/ball mills: Size range from 5 ft. x 8 ft. with ...

Autogenous and Semiautogenous mills And the product of the large AG/SAG grinding is either a finished size ready of processing, or an immediate size for further ...

FLSmidth ball mill for cement grinding. ... The size distribution of ... For ball mills operating in closed circuit,

STEEL BALL MILLS, Genemco. STEEL BALL MILLS :j~m:t _._W,Ea•• Patterson manufactures a complete line of ball mills for every wet or dry grinding process for size ...

Ball mill rpm calculation on size – Ball mill rpm calculation on size. Gulin supply Mining and construction equipment for mineral handling.

Solutions in Milling Sieving Size reduction and homogenization with ball mills RETSCH Product Navigator Milling Jaw Crushers Rotor Mills Cutting Mills

SAG is an acronym for SemiAutogenous Grinding. SAG mills are essentially autogenous mills, but utilize grinding balls to aid in grinding like in a ball mill.

Ball Mills Ball Mills, and other forms of tumbling mills such as tube mills, rod mills and batch mills form a significant type of equipment used for the size ...

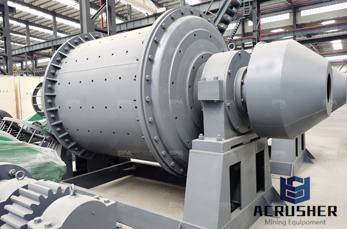

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

WhatsApp)

WhatsApp)