WhatsApp)

WhatsApp)

In the manufacture of Portland cement, clinker occurs as lumps or nodules ... The major raw material for the clinkermaking is usually limestone mixed with a second ...

Supply Management | April 2010 ©2010 AMR Research, Inc. 1 Supply ManageMent Raw Material Sourcing Strategies Are Critical to Revenue and Profit Margins

The main raw material to produce Portland cement are lime materials and clayey materials, and calibration of raw materials as well.

Reuse of water purification sludge as raw material in cement. The feasibility of partial replacement of siliceous raw material for cement production with water ...

This study reports the characterization of a talc from Cameroon as a possible source material for cement formulation. To that end, the talc sample was characterized ...

Uses of alternative fuels and raw materials in the cement industry as ... The results indicate that the presence of cement raw material at the outlet of the ...

Cement company uses Prompt Gamma Neutron Activation Analysis (PGNAA)based crossbelt online elemental analyzer to help stabilize raw meal, clinker quality.

Conveying and Storing in the Cement Industry. 2 Contents ... 12 Transport of raw material, clinker, additives and cement 14 Hopper discharge and Crusher Feeding

In cement production the chemical and mineralogical composition of raw materials as well as intermediate and finished products has to be determined to control and ...

From the quarry to raw meal feeding into the preheater. A company of Polysius ... Depending on its characteristics, the raw material needed for the cement production

Cement manufacturing raw materials. If you happen to be a geologist, the raw materials quarry is probably the most interesting part of a cement works, maybe unless ...

Raw Materials for Cement. Raw materials for cement such as limestone, clay, shale, etc. are extracted by blasting or scraping with shearer loaders.

A cement is a binder, a substance used in construction that sets, hardens and adheres to other materials, binding them together. Cement is seldom used ...

Preparation of Raw Materials for Cement Manufacture: Raw Material Preparation: Variation of Industry Capacity (annual clinker tonnes) by Raw Material Type

Fiber Cement Market report is segmented by raw material, application and end use. It is expected to grow at a CAGR of % from 2016 to 2022.

Cement processing mainly consists of the following steps: crushing, prehomogenization, homogenization of raw materials, decomposition through preheating, clinker ...

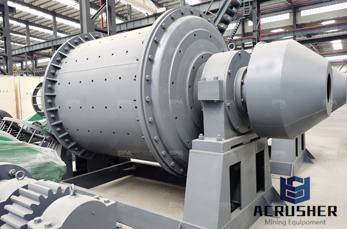

cement mill/raw material mill Zhengzhou efficiency and handling capacity operation and maintenance and reliable structure .

ACTION PLAN FOR ENHANCING THE USE OF ALTERNATE FUELS AND RAW MATERIALS IN THE INDIAN CEMENT INDUSTRY Cement Manufacturers'' Association

MCL manufactures cement through the most modern dry process method based on worldrenowned German technology. The major raw materials for cement manufacture are ...

Raw material substitution In Brief. 60% of the industry''s emissions are ''process emissions'' caused by decarbonation of limestone during the production process.

Material Mix Control Mining + in Cement Plant ... he objective of this article is the development of a novel raw material mix proportion control algorithm for a ...

Raw materials for cement manufacture. The first step in the manufacture of portland cement is to combine a variety of raw ingredients so that the resulting ...

The cement industry has for some time been seeking alternative raw material for the Portland cement clinker production. The aim of this research was to investigate ...

Cement News tagged under: raw material transport. Elevating service life The modernisation of Lafarge''s Wössingen plant in BadenWürttemberg, Germany, ...

WhatsApp)

WhatsApp)