WhatsApp)

WhatsApp)

Synthesis of Nanomaterials and Nanocomposites ... ball milling as a nonequilibrium processing ... Process Variables . The milling of materials has been a major ...

ball milling process model Size Reduction Equipment | Paul O Abb 233 Paul O Abb 233 Equipment Company is a manufacturer of new Size Reduction Equipme

ball milling process model. Milling cutter Wikipedia, the free encyclopedia. Milling cutters are cutting tools typically used in milling machines or machining ...

A system for geometric and physical simulation of the ballend milling process using solid modeling is presented in this paper. A commercially available geometric ...

Manufacturing Process Technology: 3D FEM Modeling of Ball End Milling of HSM H13 Die Steel with Cutter Inclination

Milling is a cutting process that uses a milling cutter to remove material from the surface of a workpiece. The milling cutter is a rotary cutting tool, often with ...

Surfactantassisted ball milling: a novel route to novel materials with controlled nanostructure... 5 below this critical speed to keep the ball moving.

Scalable Exfoliation Process for Highly Soluble Boron Nitride Nanoplatelets by HydroxideAssisted Ball Milling

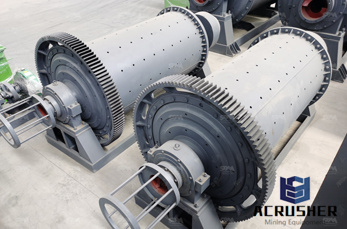

China Top 1 Supplier Ball Milling Process and Barite Ball Mill, Find details about China Ball Milling Process, Barite Ball Mill from Top 1 Supplier Ball Milling ...

Numerical modelling of highspeed ball end milling ... the ball end milling process were simulated in the finite element ... A cutting force model for ball end milling

Ball Milling Process Model. What is ball milling process . Ball mill is an efficient tool for grinding many materials into fine powder.

Refinement process and mechanisms of tungsten powder by high energy ball milling. :3000 : Contents lists available at ScienceDirectInternational ...

ball milling process model. Determination of breakage pameters in laboratory scale ball mill Ball mill was simulated by using the breakage functions and retention ...

51 BULGARIAN ACADEMY OF SCIENCES CYBERNETICS AND INFORMATION TECHNOLOGIES • Volume 12, No 2 Sofia • 2012 Grinding in Ball Mills: Modeling and Process .

36 A. Nasri et al.: 3D Parametric Modelling of Milling Cutter Geometry from Analytical Analysis process with numerical analysis, authors are constrained to

ball milling process flow. ... Model Predictive Control for SAG Milling in Minerals . ... optimizing the milling process, Ball Mill 1/2 in. and larger 1050 n/a.

LargeScale Production of EdgeSelectively Functionalized Graphene Nanoplatelets via Ball Milling and Their Use as MetalFree Electrocatalysts for Oxygen Reduction ...

ball milling process model. Our products are sold to 130 countries, being equipments in global crushing and grinding industry. With the development of our Plant, we ...

Simulation of ball end tools milling by N. Vidakis1 A. Antoniadis2, ... Using the appropriate analytical process, the geometrical model of the cutting tool follows the

China Ball Mill manufacturers Select 2017 high quality Ball Mill products in best price from certified Chinese Milling manufacturers, Plastic Machinery factory ...

The Planetary Ball Mill PM 200 is an excellent choice when a high degree of fineness is required. Grinding down to the nano range. Read more.

Determining Cutting Force Coefficient from Instantaneous Cutting Force in BallEnd Milling 742 radial direction, and established an empirical relation

Synthesis of irondoped TiO 2 nanoparticles by ballmilling process: the influence of process parameters on the structural, optical, magnetic, and photocatalytic ...

Theoretical and Experimental Study on Surface Finish ... Due to the complexity of end or ballend milling process, ... Figure 1 Tool model of a twoflute ballend mill

WhatsApp)

WhatsApp)