WhatsApp)

WhatsApp)

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area ...

Portland Cement Manufacturing Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates ...

Portland cement Manufacturing process Portland cement is made by heating raw materials rich in oxides of silicon, calcium, aluminium and iron to temperatures of around 1200 – 1400oC. The chemical reactions that occur within the ...

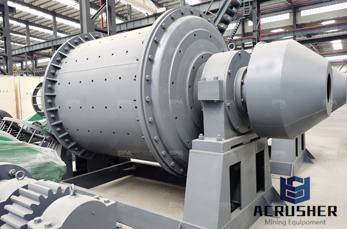

In dry and semi dry processes for manufacturing of cement, the raw materials are crushed and fed in the correct proportions into a grinding mill. In dry and semi dry processes for manufacturing of cement, the raw materials are ...

Cement manufacturing: components of a cement plant This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement ...

Guidelines for CoProcessing Fuels and Raw Materials in Cement Manufacturing Cement Sustainability Initiative (CSI) Cement Sustainability Initiative 1 Introduction 2 The Cement Sustainability Initiative 2 Background 2 ...

Cement Manufacturing Process_1 Free download as PDF File (.pdf), Text File (.txt) or read online for free. cement ... BROWSE BY CONTENT TYPE

2016/02/12· What is the process of cement manufacturing? Which raw materials it used? And which equipment it need? What amount of cement is used in M20 Grade concrete? What is the process of cement? Business Plans: Why has ...

Cement: Materials and manufacturing process . Chemically, cement is a mixture of calcium silicates and small amounts of calcium aluminates that react with water and cause the cement to set. Get Price ...

From the limestone quarry till the delivery of the final product, the following steps describe the cement manufacturing process: 1. Extraction of Raw Materials The raw materials needed to produce cement like calcium carbonate, silica ...

materials is excluded from the process. Only synthetic wastes, textile wastes as well as plastic coated paper wastes originating from welldefined production processes are being used. In the Rohrdorf cement plant approxi ...

William Aspdin had left his father''s company, and in his cement manufacturing, apparently accidentally produced calcium silicates in the 1840s, a middle step in the development of Portland cement. In 1848, William Aspdin further ...

IXMaterialsBCement1 THE MANUFACTURE OF PORTLAND CEMENT Cement is the substance which holds concrete together, which means that it is extremely widely used in our society. It has been manufactured in New ...

Cement Manufacturing Process 1. Crushing and Milling In the raw materials handling process, fi ltration systems are utilized to control emissions in the quarrying process of the plant. To minimize the loss of limestone and other ...

Cement manufacturing raw materials If you happen to be a geologist, the raw materials quarry is probably the most interesting part of a cement works, maybe unless you view the clinkering process as igneous rocks in the making.

Manufacturing Process < About Cement < Cement: Lafarge Lafarge, building better cities. World leader in building materials with topranking positions in Cement, Aggregates, Concrete. ... Alternative Raw Materials and Fuels ...

• What is Cement? • History • Overview of the Cement Manufacturing Process • Brief Overview of Kiln Operations •Wyh Bn W?rusetsa • A hydraulic cement made by finely pulverizing the clinker produced by calcining to incipient ...

Manufacturing Process < All About Cement < Cement : Lafarge Lafarge, building better cities. World leader in building materials with topranking positions in Cement, Aggregates, Concrete. Access to the content Access to the ...

A cement is a binder, a substance used in construction that sets, hardens and adheres to other materials, binding them together. Cement is seldom used solely, but is used to bind sand and gravel together. Cement is used with ...

めまれている· Mixing of raw materials The raw materials such as limestone or chalk and shale or clay may be mixed either in dry condition or in wet condition. The process is accordingly known as the dry process or the wet process of mixing. Dry ...

The process for making Portland cement Materials that contain appropriate amounts of calcium compounds, silica, alumina and iron oxide are crushed and screened and placed in a rotating cement kiln. Ingredients used in this ...

Ash Grove Cement and Related Materials (Manufacturing Process), Portland cements are hydraulic cements composed primarily of hydraulic calcium silicates. ... Manufacturing Processes An Overview Portland cements are ...

Most Common materials which is used to manufacturing cement is includes limestone, shells, and chalk combined with shale, clay, slate, blast furnace slag, silica sand, and iron ore. These ...

Manufacturing process < All about Cement < Cement : Lafarge Lafarge, building better cities. World leader in building materials with topranking positions in Cement, Aggregates, Concrete. ... Ensuring a good yield The reliability ...

WhatsApp)

WhatsApp)