WhatsApp)

WhatsApp)

Wet and semiwet process cement kilns ... It is this thin layer of water that allows the slurry to flow. As the separation of particles increases with increasing ...

Table 2: Composition of portland cement with chemical composition and weight percent. When water is added to cement, each of the compounds undergoes hydration and ...

Called "cement additives", these minerals are used in varying proportions during the last phase of the cement production process. The additives make it possible to ...

Portland Cement Association. 5420 Old Orchard Road; Skokie, Illinois ; ; 1150 Connecticut Avenue, NW, Suite 500; Washington, DC

Jul 23, 2016· Reader Approved wiki How to Mix Cement. Three Methods: Preparing the Dry Mix Mixing in Water Completing the Process Community QA. Whenever a .

Graham O''Hare of Cathedral Stonemasons discusses the merits of adding Portland cement to lime mortars and renders, and the risk of segregation.

Drying and Primary Grinding. The essential additives quartz, sand and iron ore are added to the homogenised material and this mixture is then ground to a powder with ...

The table also includes an indication of the primary uses and benefits, along with the cements that they can be used with. The primary effects of the cement ...

Since its establishment in 2006, Al Khalij Cement Company (AKCC) has stood for Health Safety, Quality, Sustainability, Efficiency and Growth.

Technology Overview. Blue Planet''s new biomimetic carbon capture and mineralization technology utilizes several patented scientific breakthoughs.

Rapid Set® Cement. When you''re working on a concrete repair project and time is critical, choose Rapid Set® Cement. Rapid Set Cement is a fastsetting hydraulic ...

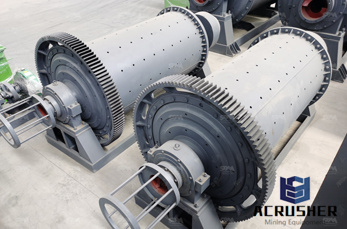

CEMENT GRINDING OPTIMISATION Dr Alex Jankovic, Metso Minerals Process Technology AsiaPacific, Brisbane, Australia email: metso

Dry, semidry, semiwet and wet processes are the four main process routes that are used for the production of cement. Dry processes are considerably more energy ...

A cement is a binder, a substance used in construction that sets, hardens and adheres to other materials, binding them together. Cement is seldom used solely, but is ...

Information about Grouts and Anchors. Cement and Epoxy resin grouts for construction applications including grouting baseplates, machine bases, rails and all sorts .

In experimenting with materials other than what would be considered "traditional", I have found that white portland cement works best for my style and subject ...

Cement Production Process Three production steps are distinguished in the description of the production of cement: zPreparing raw materials: Mixing/homogenising ...

An electric current is sent by wire to a perferating (perf) gun. The charge shoots small holes through the casing, cement, and a short distance into the shale.

The differences between additives for hydraulic fracturing in different countries are the type of chemicals used (hazardous, nonhazardous), the disclosure of ...

Cement is a fine powder, obtained from the calcination at 1,450°C of a mix of limestone, clay, and iron ore. The product of the calcination process is clinker—the ...

Welcome to NYCO, a Member of IMERYS. At NYCO, we are proud of the excellent reputation we have earned during our 60 years of operation and are committed to ...

More about Mortars and Additives. To better protect your premium stone and tile, TEC® crack isolation mortars provide you with some of the most advanced solutions in ...

How to Use Cement Additives. Cement is a man made mineral based powder which goes through a chemical change or reaction when mixed with water. First it becomes like ...

How I Cement Roof Tiles. Welcome to Daniel''s Roof and our guide to securing and cementing roof tiles.

WhatsApp)

WhatsApp)