WhatsApp)

WhatsApp)

Small size, big energy savings 2 Proven technology Today the airswept vertical roller mill is the standard solution for coal grinding installations.

Our slag vertical mill is typically designed to deal with industrial waste residues ... Slag powder vertical roller mill adopts the internal negative pressure system ...

The coal vertical roller mill has less dust, low noise, high efficiency granular composition, and excellent combustion performance due to its special design and ...

Verical Roller Mill. Vertical roller mill is MCC company to solve the industrial mill production is low, high energy consumption, technical difficulties, the European ...

Academy of Information Technology Vertical Roller Mill. Vertical Roller Mill. Vertical roller mill is to solve the industrial mill low output, energy consumption ...

OPERATIONAL EXPERIENCE FROM THE UNITED STATES'' FIRST VERTICAL ROLLER MILL FOR CEMENT GRINDING By: Mark Simmons Production Manager Salt River .

By replacing ball mills with vertical or horizontal roller mills in raw material preparation, energy savings of 610 kWh/traw materials (depending on grindability of ...

Vertical roller grinding mill: In recently year, because of the energysaving advantage in cement industry by vertical roller mill, the

Working Principle of vertical roller mill: Material through the feed tube fell on the center of grinding plate, centrifugal force generated from the rotation of ...

VM series Vertical Grinding Mill is a kind of large scale powder mill which is designed specially to solve the problems of low capacity and high consumption of ...

LM vertical mill machine is developed and launched by Zenith, sets medium crushing, drying, grinding, classifying in the grinding industry.

Test results of energy optimized grinding of three different mineral materials • Comparison of vertical roller mills with tumbling mills on the lab and pilot scale

LM series vertical roller mill is one advanced powder making mill which is developed through many years'' research experience and bringing in the latest mechanical ...

Mill (grinding) Attrition Mill; A ... There are several advantages to the tower mill: low noise, efficient energy usage, and low operating costs. ... roller mill, an ...

Vertical Roller Mill. water and energy are precious resources and without them life would not be as we know it today. » Learn More. Energy Conservation in Vertical ...

201159 · China)Key words: vertical roller mill (VRM); cement grinding; preparation process Abstract: As one of the mixture of cement, ... large mount of energy saving, .

Vertical roller mill combines the drying, grinding and separation processes. Cement vertical roller mill, vertical cement roller mill for finish cement grinding.

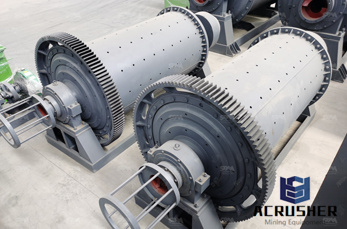

Ball mills, that are commonly used for finish grinding, have high energy demands, consuming up to 3042 kWh/t clinker depending on the fineness of the cement.

A NEW GEARBOX GENERATION FOR VERTICAL ROLLER MILLS By: Dr. Roger Raeber, Vice President Engineering, MAAG Gear AG Ulf Weller, Senior Design .

730b Vertical Roller Mill,Energy Laboratory Planetary Ball Mill, Find Complete Details about 730b Vertical Roller Mill,Energy Laboratory Planetary Ball Mill ...

vertical mill energy industry Grinding Mill China. According to customers'' requirements, Gulin success in absorbing foreign experience and worldadvanced ...

Vertical roller mill . Vertical roller mill integrates the grinding, drying, separation and transportation into one compact unit, thus . simplifying the process layout.

Ball mill, vertical roller mill, ... Energy saving effect is obvious vertical roller mill for more than 10 ... the vertical roller mill''s energyefficient cement ...

Vertical roller mill Wikipedia, the free encyclopedia. Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in ...

WhatsApp)

WhatsApp)