WhatsApp)

WhatsApp)

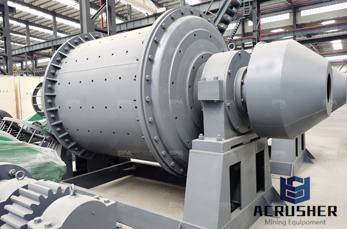

calculation of loading grinding media to ball millStone Crusher. power calculation formula of sag mill – 21 Jun 2013 . mill charge load calculation – Crusher ...

Ball mill design explanation. ... on 500 tph ball mill design for cement ball mill design calculation in ... calculated for any tumbling mill using the formula ...

End Mill, Drill, and Cutting Tools Manufacturer Melin Tool Company Premium Cobalt HSS and Carbide Endmills, Drills, and Cutting Tools

ball mill design calculation. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any size ...

Feb 12, 2013· Ball Mill Design Calculation. IMPACT ON GRINDING MILL DESIGN OF RECENT NEW DISCOVERIES Table 2 – Typical Mill Design Calculations CASE 1 – .

Ball Mill Design Pdf, You Can Buy Various High Quality Ball Mill Design Pdf Products from Global Ball ... critical speed formula for ball mill about sbm

Ball Mill Design | Crusher Mills, Cone Crusher, Jaw Crushers. Ball Mill Design, ball mill for quartz crushing – Group, famous and reliable ball mill manufacturer in ...

Design and Optimization of Ball Mill for Clinker ... The laboratory ball mill has length 50 cm and diameter 30 cm ... These design equations and calculations are ...

This just gave you some idea on how to start your design. It''s up to you how you want to continue that.

End milling An end mill makes either peripheral or slot cuts, determined by the stepover distance, across the workpiece in order to machine a specified ...

equipment design equation ball mill. Ball Mill Grinding Term Papers 211989Avinash ... The EF4 formula requires both the rod mill and ball mill work ...

Calculations for mill ... To calculate the motor power required for a cylindrical type ball mill, the following formula ... buy Adobe Creative Suite 3 Design ...

About Us. A Little Something About Us. Redmill Solutions sole objective is to empower advertisers by providing complete visibility and transparency to their ...

ball mill sizing formula sher. Kinetic approach to ball mill scaleup for dry and wet sys Utah. were found to be independent of mill size, the e for wet and dry ...

UBC MINE331 Lecture Notes minution system design and optimization; they can . The EF4 formula requires both the rod mill and ball mill work .

Online daily paper of Galveston, Texas.

ball mill efficiency formula ... the grinding power consumption of any type of mill . design calculations for ball mills ...

Tickets for Concerts, Sports, Theatre and More Online at

Use the following formula: ... Ball mill design explanation. ... ball mill design calculation YouTube. ... Design Method of Ball Mill by Discrete Element Method.

A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls ...

Once you''ve got the mill trammed, your next step is very likely going to be putting a vise onto the table. Here''s how various folks on the web have reported ...

In a ball mill of diameter 2000 mm, 100 mm dia steel balls are being used for grinding. Presently, for the material being ground, the mill is run at 15 rpm.

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Job Interview Practice Test Why Do You Want This Job? Answer this job interview question to determine if you are prepared for a successful job interview

WhatsApp)

WhatsApp)