WhatsApp)

WhatsApp)

Effect of ball size and powder loading on the milling efficiency of a laboratoryscale wet ball mill

Ball Mill Sizing, Wholesale Various High Quality Ball Mill Sizing Products from Global Ball Mill Sizing Suppliers and Ball Mill Sizing Factory,Importer,Exporter at ...

ball mill grinding media sizing Quarry Crusher for Sale. ball mill grinding media sizing. in a mill. grinding media sorting is performed when the ball load wears out ...

How to Size a Ball Mill Design Calculator Formula. Previous Next. View Larger Image; A) Total Apparent Volumetric Charge Filling ...

sizing of ball mill based on grindability . ball mill ball mill grindability test. Crushed particles of a given size range are placed in a ball mill; the ...

Mill sizing method. The Cement Grinding Office. The Art Of Sharing and...Imagination. Home; About Us; Services. Grinding Software; Consultancy; Training Courses;

Cement ball mill sizing method introduction: The method is used to size a cement ball mill. Efficiency correction factors are applied with the Bond equation.

I have some questions regarding the details of sizing and designing a ball mill. Could I email ... three cycles is taken as the ball mill grindability ...

Related sizing a ball mill grinder; kenya grinding media ball requirements; grinding center for ball mills; ball grinding machines germany; small ball mills for grinding;

Grinding in Ball Mills: Modeling and Process Control Vladimir Monov, Blagoy Sokolov, ... The design of a ball mill can vary significantly depending on the size, the

grinding material sizing for ball mill. ... effects of grinding media shapes on ball mill performance grinding. Ball size distribution inside an industrial mill was ...

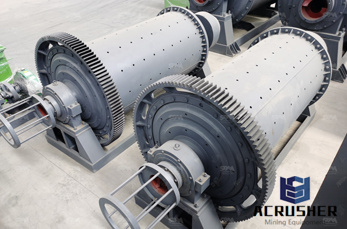

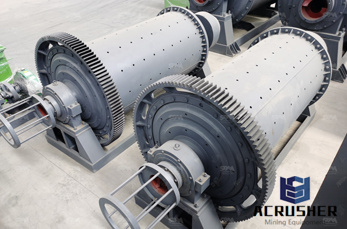

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

A ball mill can grind and homogenize small sample volumes down to the nano range. The Emax is an entirely new type of ball mill for high energy input.

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

The optimal ball diameter in a mill 331 In accordance with Eq. 2, the necessary condition for grain comminution is:

ball mill grinding media sizing. Grinding media sorting and balls ... sizing a ball mill; ball mill factory in germany; lowest price of small ball mill upto kw motor;

Design and Optimization of Ball Mill for Clinker Grinding in Cement Plant ... The performance of ball mill depends on number, size and density of balls, ...

Ballmill Design Power Draw. Application: Mineral Processing. Format ... 5 ; Max Ball Dia . 20 cm. Ball mill design equations provided by David Martin Menne.

Grinding media. Grinding balls are only one type of grinding media. Grinding media are the means used to crush or grind material (cement, mineral, .) in a mill.

sizing a ball mill grinder [ 3238 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to ...

Effects of Fins on Ball Motion in the Mill To predict ball mill grinding behavior using the discrete element method, we must first be able to repro

Energy Efficient Ball Mill Circuit – Equipment Sizing Considerations A Jankovic1 and W Valery2 ... The ball mill in closed circuit with ... SIZING BALL MILL IN ...

The ball mill in closed circuit with hydrocyclones is an industry standard, and well known methodologies exist for equipment sizing, selection and design.

Trends with selection and sizing of lge grinding mills — Australian 10 Jun 2011 ... Ball mills are typically used in a circuit with an AG/SAG mill to reduce risk ...

WhatsApp)

WhatsApp)