WhatsApp)

WhatsApp)

Raw materials Understanding Cement Raw materials used in cement manufacturing. . The most common raw rock types used in cement production are: Line (supplies ... Cement manufacturing components of a cement plant For ...

2017/08/20· Even construction professionals sometimes incorrectly use the terms cement and concrete interchangeably. Cement is actually an ingredient of concrete. It is the fine powder that, when mixed with water, sand, and gravel or ...

Portland cement, the most common type of cement in general use around the world as a basic ingredient of concrete, mortar, stucco, and nonspeciality grout, was developed in England in the mid 19th century, and usually originates ...

cement manufacturing process use of crusher JAPANESE CLEAN TECHNOLOGIES FOR SOUTH AFRICAN CEMENT INDUSTRY ... japanese japanese clean technologies technologies for south african cement industry cement ...

Insulation and heat resistance hydraulic cement aggregates comprising of white Portland cement, with or without additives and filler, magnesium oxide, zirconium compounds, marble, dolomite, granite, sand, talc, clays calcined ...

Cement Manufacturing Process The raw materials needed to produce cement (calcium carbonate, silica, alumina, and iron ore) are generally extracted from limestone rock, chalk, shale, or clay. These raw materials are won from ...

The possibility of using basalt rock, which has relatively limited uses, instead of clay in cement industry is investigated. Two clinker mixtures were prepared according to the composition: (87 wt.% limestone+12 wt.% clay or basalt ...

STAGES OF CEMENT MANUFACTURING lime stone mining Opencast mining refers to a method of extracting rock or minerals from the earth by their removal from an open pit or borrow. These mines are used ...

It can be a component of bricks and cement. CONGLOMERATE: A sedimentary rock with a variable hardness, consisted of rounded or angular rock or mineral fragments cemented by silica, lime, iron oxide, etc. Usually found in ...

2017/02/28· If you think of bricks as artificial rocks, cement might be considered artificial lava—a liquid stone that is poured into place where it hardens into solidity. Cement and Concrete Many people talk about cement when they ...

2008/01/20· Many people use the words cement and concrete interchangeably. However, these are actually two, somewhat different things. Cement is the grey powdery stuff that when mixed with sand, rock, gravel and water forms ...

IXMaterialsBCement1 THE MANUFACTURE OF PORTLAND CEMENT Cement is the substance which holds concrete together, which means that it is extremely widely used in our society. It has been manufactured in New ...

cement: in general, adhesive substances of all kinds, but, in a narrower sense, the binding materials used in building and civil engineering construction. Cements of this kind are finely ground powders that, when mixed with water, set ...

Process and Technology to Manufacture Cement Product Cement product is a binding we will look at the ingredients that is being used in the process and manufacturing of one of the most important cement JKLakshmi ++get price++

Generic Concrete Products with Portland Cement Product Selection and Description Portland cement concrete, typically referred to as "concrete," is a mixture of portland cement (a fine powder), water, fine aggregate such as sand ...

Cement manufacturing raw materials If you happen to be a geologist, the raw materials quarry is probably the most interesting part of a cement works, maybe unless you view the clinkering process as igneous rocks in the making.

Portland cement is the most common type of cement in general use around the world as a basic ingredient of concrete, mortar, stucco, and nonspeciality grout. It was developed from other types of hydraulic lime in England in the ...

Jaypee Group Businesses CementManufacturing Process The cement manufacturing process starts from the mining of line, which is ... The LS Crushers crush the line to minus 80 mm size and discharge the... Manufacturing ...

, Vol. 33, No. 2, 2011 147 Raw Mix Designing for Coal as a Fuel in Cement Kiln as a Major Fuel and its Impact on Clinker Parameters 1NOORULAMIN* AND 2KHURSHID ALI 1Department of Chemistry, Abdul ...

The first step in making concrete is to prepare the cement. One type of cement, Pordand cement, is considered superior to natural cement because it is stronger, more durable, and of a more consistent ...

Manufacturing process < All about Cement < Cement : Lafarge Lafarge, building better cities. World leader in building materials with topranking positions in Cement, Aggregates, Concrete. Access to the content Access to the ...

Manufacturing process < All about Cement < Cement : Lafarge A line quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km. . They are three types of clay used in cement manufacturing, namely silty ...

BBC GCSE Bitesize: Uses of limestone Limestone (CaCO3) can be used as a building material and in the manufacturing of iron Glass heated with sand and soda (sodium carbonate) Cement heated with clay in a kiln Concrete ...

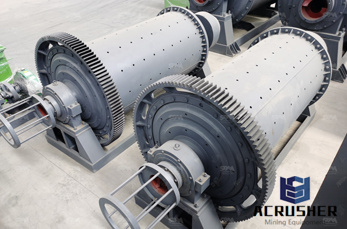

crusher used in cement manufacturing PRODUCTS SBM Crushers, Grinding Mill, Mobile Crusher ... K Series Mobile Crushing Plant. Based on more than 30 years manufacture experience, millions of equipment units installation ...

WhatsApp)

WhatsApp)