WhatsApp)

WhatsApp)

Cement Manufacturing Process Phases. Production of cement completes after passing of raw materials from the following six phases. These are; Raw material extraction ...

Haward Technology has delivered internationallyaccredited courses for major oil and gas, power and process companies through its public and inhouse courses while ...

The initial step in ceramic tile manufacture involves mixing the ingredients. Sometimes, water is then added and the ingredients are wet ...

PARTICULAR PROVISIONS CLAUSE PAGE 1 OF 5 USES WITH ADVERSE AMENITY POTENTIAL Purpose To define those types of industries and warehouses which if not ...

The presence of mists in a chlorine process gas stream can cause problems associated with product purity, safety and decreased production because of increased ...

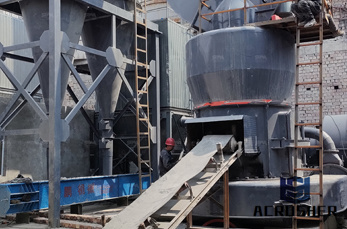

Reducing greenhouse gasses emissions by fostering the deployment of alternative raw materials and energy sources in the cleaner cement manufacturing process

4 MANUFACTURING PROCESS The process of manufacture of cement concrete hollow blocks involves the following 5 stages; (1) Proportioning

Your Ultimate Pulp and Paper Dictionary on the Web

MDF and DSF The New Ultra High Strength Concretes A new generation of ultra high strength concretes has been developed to rival the properties of metal!

Integrated cement plants are recognised as a source of undesirable airborne emissions. In an attempt to moderate the effects of these on the environment and local ...

The chief compound which usually form in process of mixing: 1triclcium silicate () 2Dicalcium silicate () 3tricalcium aluminates ()

Dry, semidry, semiwet and wet processes are the four main process routes that are used for the production of cement. Dry processes are considerably more energy ...

In the cement pyroprocessing process it is important to keep in mind that waste materials combust and burn at different temperatures under different conditions.

Concrete is a composite material composed of coarse aggregate bonded together with a fluid cement that hardens over time. Most concretes used are limebased concretes ...

Environmental, Health, and Safety Guidelines CEMENT AND LIME MANUFACTURING APRIL 30, 2007 4 WORLD BANK GROUP • Developing a staged combustion process .

Australian Government Department of Education and Training

Global Carbon Dioxide Emission from Cement Production Process In this paragraph we provide an estimate of both process and energy emissions from global cement

A cement is a binder, a substance used in construction that sets, hardens and adheres to other materials, binding them together. Cement is seldom used solely, but is ...

Modeling Of Sokoto Cement Production Process. Open Access Journal ...

1. PRODUCT Description Viroc® Cement Bonded Particle Board Viroc is a composite material, composed by a compressed and dry mixture of pine wood particles and cement.

Wet process kilns. The original rotary cement kilns were called ''wet process'' kilns. In their basic form they were relatively simple compared with modern developments.

In completion of oil and gas wells, cement isolates the wellbore, prevents casing failure, and keeps wellbore fluids from contaminating freshwater basic ...

How cement is made and history of Portland Cement

Web portal for buildingrelated information with a "whole building" focus provided by the National Institute of Building Sciences. Areas include Design Guidance ...

WhatsApp)

WhatsApp)