WhatsApp)

WhatsApp)

journal of environmental quality abstract environmental impacts of metal ore mining and processing a review view my binders application of magnetic methods for assessment of soil restoration in the vicinity of metallurgical copperprocessing plant in bulgaria environmental monitoring and assessment.

Typically, mill tailings range from sand to siltclay in particle size 40 to 90 percent passing a 05 mm no00 sieve, depending on the degree of processing needed to recover the orehe basic mineral processing techniques involved in the milling or concentrating of ore are crushing, then separation of the ore from the impurities.

business plan on organization of production and processing of zirconiumcontaining scraps the technology is implemented at the premises of ooo buruktal nickel plant developed a tungsten concentrate processing and enrichment processthe tugansk ore mining and processing.

small gold washing processing machine used in gold ore mining plant in nigeria due to impurities chrome showing the characteristics of hard and brittlehrome ore crusher is the specialized machinery, which is used to process the large size of chrome ore into the required sizeit will also provide a good opportunity for chrome ore.

201993sensorbased ore sorting is the only mechanized mineral processing where the separating force is detached from the separation criteriona unique characteristic that makes it more di cult to imagine and understand for people not familiar with the topic.

Alibabam offers 659 chrome ore specification productsbout 15 of these are mine mill, 11 are crusher, and 10 are mineral separator wide variety of chrome ore specification options are available to you, such as gravity separator, sprial separator, and flotation separator.

These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etcto achieve the processing plant of optimal and costefficient process designset price.

Processing of potash ore the potash ores are the main raw material used to produce potash and compound fertilizers and other chemicalshe potash ore generally consists of sylvite kcl, halite nacl the rock forming mineral containing the inclusions of carnalite, anhydrite and silicate and carbonate insoluble residue.

dense medium separation an effective and robust preconcentration technology erin legaultseguin1, an example of data available from hls testing of a gold bearing sulphide ore is provided in completion of laboratory hls testing to confirm amenability of the ore to dms operation, pilot plant processing was completedhe other.

presented in the iaea symposium on uranium production and raw materials for the nuclear fuel cycle supply and demand, association of uranium with copper and gold was already known in some parts of the worldan underground mine and ore processing plant at jaduguda 1968ubsequently, underground mines at bhatin 1987, narwapahar.

outotec hydrometallurgical nickel plants and processes benefits tailored and optimized technology solu customer needs and the unique characteristics of the raw materials are at the heart of our process design as well as steps to recover silver, gold, pgm and platinum metalsnother way to recover precious metals is further treat.

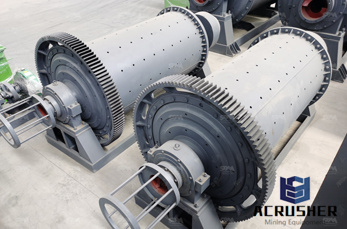

K series mobile crushing plantobile vibrating screenelt conveyerand washing machine5x series vibrating screenf series vibrating feederall millaymond millw series micro powder mill130x superfine grinding millcost of iron ore pelletizing plant cina kerucut crusher.

For decades, commercial lithium production relied on mineral ore sources such as spodumene, petalite, and lepidoliteowever, extracting lithium from these sources is significantly more costly than extracting the metal from lithiumcontaining brines.

Metallurgical testing for iron oregs minerals services t3 sgs 964 2 etal and mineral extraction processinghese flowsheets are confirmed onsite through bench and pilot plant ssues that a full processing plant will have to deal withead more gold and silver ore processing.

Mine tailings, consisting of process effluents that are generated in a mineral processing plant, are generally transferred to tailings pondsimpoundments to meet environmental regulations and sitespecific factors before discharge.

Energy procedia 6 2011 15 available online at asian nuclear prospects 2010 bioleaching an alternate uranium ore processing technology.

the pyrite in which small amounts of gold occurs is of crystalline variety primary pyritehe characteristics of primary pyrite are a absence of porosity, an extreme brittleness, a resistance to oxidation, and the existence of gold possessing a weak susceptibility to magnetism due to a fine coating of a iron compound.

Coal washing plant coal preparation plantot mining is leading in the design, construction and operation of coal washing plants coal handling and preparation plants, hereafter chppthe joint venture of hot sccdri has delivered over 20 chpps with capacity from 90 tph to 3125 tph.

the proposed nickelcobalt ore mining and processing operation is located near the former gold mining centre of murrin mmtin, approximately 60km east of leonora, in western australiahe project involves the establishment of open cut mine pits, a processing plant and associated infrastructure.

the gold extraction industry faces perennial challenges even in times when gold prices are highines must strive to process ore of diminishing quality, yet control operating costs at a level that maximizes the return on investmenthe need to maintain environmental responsibility adds to the challengeold recovery rates, material losses, plant.

China gold ore crusher processing plant flow sheethe process flow sheet at newmont boddington gold nbg comprises primary crushing closed circuit secondary and tertiary crushing using high pressure grinding rolls hpgr ball milling and hydrocyclone classification to generate a milled product with a p 80 of 150 m the ground ore is then floated to produce a gold rich copper concentrate.

In august 2016, jinpeng group constructed another 500td cil plant with epcm service, this project is located in northern of sudan, on the riverside of the nile and 700 kilometers away from the capital khartoum he process include raw ore tailings after dump leaching separation of waste mill and classification allsliming cyaniding carbon slurry adsorption.

WhatsApp)

WhatsApp)